Value chains for sustainable production, use and cycles of Textiles (Telavalue)

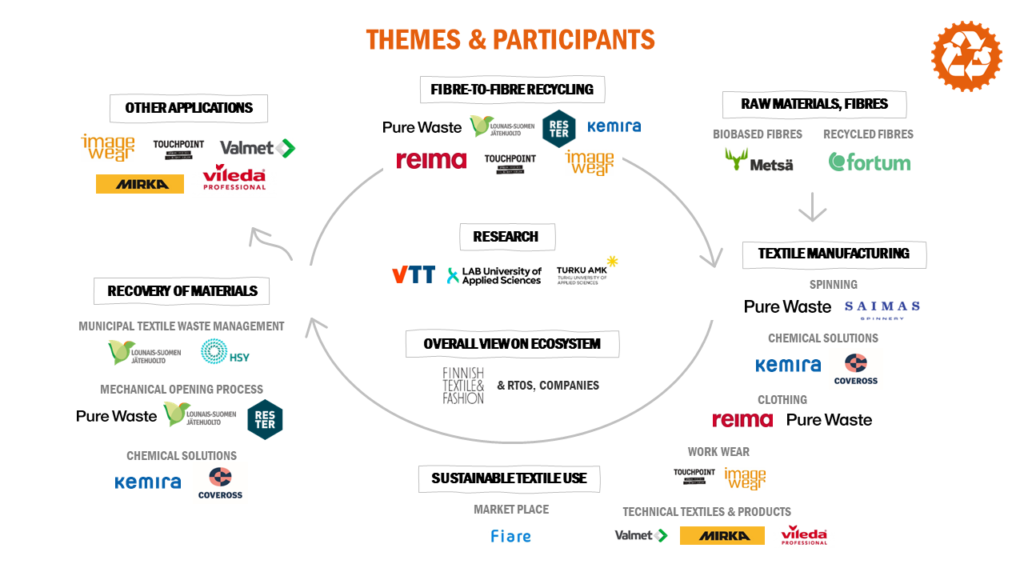

The vision of Telavalue BF project was to solve sustainability and waste problems related to current textile system through circular economy. Telavalue was Business Finland Co-Innovation project which consisted of the public research project and six company projects.

The main objectives of the public research project were

- to support and build value chains for sustainable production, use and cycles of textiles

- combine recycled and novel bio-based fibres as basis for sustainable Finnish textile production

- ensure efficient product use via circular design and novel business models

- ensure efficient textile material circulation via recycling of different kinds of discarded textiles from households as well as companies including also technical textiles

The themes of the project were, for example, sustainable and circular textile business, application of novel bio-based and recycled fibres in textile products, new circular business models, and material circularity.

The public research project carried out by VTT, LAB University of Applied Sciences and Turku University of Applied Sciences and funded by Business Finland and 17 companies and other organizations. The project started in February 2022 and ended in July 2024.

Telavalue project was directly linked to earlier Telaketju project and ExpandFibre ecosystem.

Baltic2Hand

The Baltic2Hand project aims to improve textile reuse and reduce textile waste by improving the business models of second-hand companies.

Generally, the underuse of textile is caused by a lack of circularity in the textile and fashion industries leading to an overflow of textile waste. All CB countries must work together to find solutions to prevent unnecessary used textile exports from Finland and Sweden to Estonia, Latvia, and elsewhere.

The targeted improvements in textile reuse and reduce textile waste, which will be achieved through improving the business models of second-hand companies and other companies that want to add a second-hand operation to their business; and also through enhancing consumers’ use of second-hand market as both sellers and consumers.

Read more about other projects

PaaS Pilots – Product as a Service pilots

The project PaaS Pilots – Product as a Service pilots aims to find out the features that make product as a service model attractive to customer and challenges concerning the implementation of such features. Product as a service model is one of the circular business models: instead of selling, the company leases the product for the customer, for example, in which case the customer is free from the responsibilities that come with the ownership, such as maintenance.

This is studied on the basis of earlier produced data and two pilots realized in this project. In addition, the pilots serve as examples of how the service can be implemented in practice.

The interesting aspects are, for example, importance of sustainability, affordability, easiness, proper product qualities and other values in connection with customer acceptance, and how they are taken into account in product and service design. The results will be shared openly mainly in English but there will also be a Finnish summary of the findings.

The project is carried by Turku University of Applied Sciences, VTT and LAB University of Applied Sciences and funded by Sitra. The project started in September 2021 and ends in June 2022.

Project result: Heinonen, E., Kalliomäki, H., Petänen, P. et al. (2022): Guide for developing Product as a Service business.

Telaketju 2 BF project

Telaketju 2 BF project included new types of circular business models aiming at material efficiency and the extension of the life cycle of textiles, as well as the recycling business.

The project themes were

- new circular business models

- the impact of product design on the age and recyclability of a product

- the application of product information in a circular economy

- the collection and pre-sorting

- the identification and sorting of textiles

- the classification of recycled material for standardization

- tools for communicating circular economy solutions in companies’ value networks.

The Telaketju 2 BF project consisted of companies’ development projects and a public research carried by VTT, Turku University of Applied Sciences and LAB University of Applied Sciences, which was funded by Business Finland and more than 20 companies and other organizations. The Telaketju 2 BF project began in May 2019 and ended in April 2021.

Read the Telaketju 2 BF final report here.

Research organizations: VTT, Turku University of Applied Sciences and LAB University of Applied Sciences

Companies that had their own project: Lounais-Suomen Jätehuolto. Pure Waste Textiles, Touchpoint and Image Wear

Companies and organizations that participated in the financing of the BF project: Valmet, Reima, Lounais-Suomen Jätehuolto, Freudenberg, BlackModa, Infinited Fiber Company, Finnish Textile and Fashion, Suonpää Companies, Porin Villa and Cover, Globe Hope, Nosh Company, Paptic, Fida , Partex Workshop, PK-seudun kierrätyskeskus, Sideflow, Spinning mill Black Sheep, Aijuu, Vaatepuu, Painovoima ry, Verstas247, Mirka and Topper Uniform

Telaketju TEM

Ministry of Economic Affairs and Employment granted support for circular economy investment and development projects for Lounais-Suomen Jätehuolto (LSJH) for the waste textile processing plant project. The implementation of the plant was to be started in stages. In addition, the project was funded by almost all Finnish municipal waste facilities, as the recycling plant is intended to handle the disposal of all Finns’ waste textiles in the future.

The project started in August 2018 and lasted for two years. The project enabled the launch of a pilot plant for a waste textile processing plant and the planning of subsequent phases. The pilot was carried out in close cooperation with domestic textile users.

Coordination: Lounais-Suomen Jätehuolto Oy, Sini Ilmonen

Steering group: Suomen Kiertovoima KIVO and member institutions, VTT Technical Research Center of Finland, Turku University of Applied Sciences Oy, Lahti University of Applied Sciences Oy, Finnish Textile & Fashion

Telaketju Tekes

The focus of the Telaketju Tekes project was to develop processes at different stages of the value chain and to find new users and utilization methods for different textile fractions. The goal was to promote the circulation of textiles and at the same time create added value for their own operations and create new business.

The Telaketju Tekes project consisted of companies’ research and development projects and a public project, in which the research partners were VTT and the Turku University of Applied Sciences and Lahti University of Applied Sciences, as well as the companies participating in the project.

The research themes were, e.g.

- the risks and opportunities of textile recycling

- the environmental impact of different material fractions

- the suitability of different technologies for waste textile materials

- the business opportunities of the textile recycling entity in Finland.

The Tekes project lasted until the end of September 2018.

Research organizations: VTT, Turku University of Applied Sciences and Lahti University of Applied Sciences

Companies that had their own Tekes project: Pure Waste Textiles, Touchpoint, Soften, Recci, Tramel and Remeo

Other companies involved in the cooperation: Paptic, MJV Sähkö, Ilmakunnas, Finlayson, Lounais-Suomen Jätehuolto, SOL Laundry Services, Infinited Fiber Company, Suominen, Globe Hope and Familon

Telaketju YM

The aim of the collection and sorting pilot project was to develop a comprehensive collection and sorting system for waste textiles in Finland and to increase the recycling rate of municipal waste by improving the processing of waste textiles for recycling and reuse. The regional experiments were used to find the best solutions for the various stages of the Telaketju chain, focusing on the collection, sorting and processing of textile waste.

The pilot project addressed the key challenges of collecting and sorting waste textiles and supported the introduction and dissemination of good practice nationwide. The aim was that with the solutions to be developed, Finland would receive as export products both the overall concept of recycling and Finnish technology and robotics, as well as new end products and textile raw materials.

The pilot project lasted until the end of 2018. The project consisted of three experiments.

Funded by the Ministry of the Environment, Suomen Kiertovoima KIVO, Lännen tekstilihuolto, the City of Turku, Ekokem, Finnish Textile & Fashion and the participants in the experiments with self-financing.

The first experiment developed three entities, the first of which focused on communication and clarification of terminology and legislation used in textile recycling. The main target group for the communication was consumers, and the experiment created a social media strategy and a series of blog posts. The communication expert was Valonia. The Finnish Environment Institute was responsible for clarifying terminology and legislation. The aim was to provide clear guidelines for organizations and companies collecting textiles. Both tasks were performed in close cooperation with Telaketju Tekes project.

Coordinated by: Lounais-Suomen Jätehuolto Oy, Sini Ilmonen.

Valonia, Syke and Turku University of Applied Sciences were involved.

The second experiment focused on the possibilities of source separation and examined the effectiveness of communication and counseling on the recycling behavior of residents. A post consumer textile collection pilot was organized in Turku. The focus was on how much still usable textile was put in the collection bins that would actually belong in the boxes of the charities. In addition, the quantity and quality of the textile waste was examined, as well as the number of items that should not been in the collection bins, such as mattresses, books, tools and Christmas decorations. The pilot was organized also in Rauma and in Eastern Uusimaa.

Coordinated by: Lounais-Suomen Jätehuolto Oy, Miia Jylhä.

UFF, Ekopartnerit and Akseli real estate services included.

The third experiment focused on the training for a textile sorter in Finland. The experiment, called Telakoulu, piloted the training for a textile sorter and examined the role and significance of manual sorting in the pre-treatment of post consumer tectiles. Turku University of Applied Sciences was involved in all experiments.

Coordinated by: PK-seudun kierrätyskeskus, Pia Engström, Helsinki.

Fida International, the Nextiili and the Texvex Workshop participated in.

Telaketju AIKO

The AIKO funding supported the implementation of the first phase of a domestic waste textile processing plant in Southwest Finland and the planning of subsequent phases. The AIKO funding enabled the market survey of waste textile products and the preparation of the plant’s business plan. The project provided support for the development of high-quality sorting so that the materials to be recycled could be used to best meet the needs of companies that utilize waste textiles. The total budget of the project was 73 000 euros. The year-long project started during May 2018.

Coordination: Lounais-Suomen Jätehuolto Oy, Sini Ilmonen.

Steering group: Suomen Kiertovoima KIVO and member institutions, VTT Technical Research Center of Finland, Turku University of Applied Sciences Oy, Lahti University of Applied Sciences Oy, Finnish Textile & Fashion