Chemical fibre-to-fibre recycling

The aim of the demo was to investigate the chemical recyclability of waste textiles containing man-made cellulosic fibres and determining the changes in properties of recycled fibres after cycles of dissolution and regeneration.

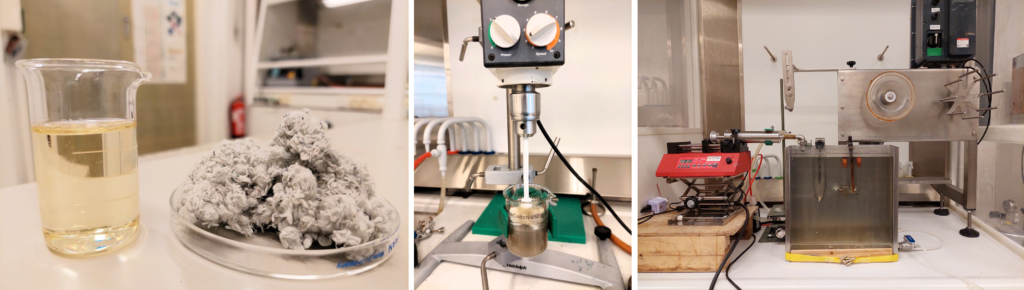

After chemimechanical pre-treatments for adjustment of intrinsic viscosities and removal of impurities from feedstocks, waste textile samples containing either viscose, lyocell, cellulose carbamate fibres, and/or cotton were dissolved into ionic liquid [EMIM][OAc] to prepare dopes for dry-jet wet spinning trials. Proper cellulose contents for dopes were determined by viscometry of spinning dopes, after which the final spinning solutions were prepared. Water was used as a coagulating bath during spinning, after which the fibres were dried for further analyses. Spun fibres were further dissolved into the same ionic liquid for the next spinning cycle.

Waste textiles containing man-made cellulosic fibres such as viscose and lyocell can be chemically recycled, using suitable methods for pre-treatment, by dissolving material into ionic liquids and spinning of fibres by dry-jet wet-spinning method, even with low intrinsic viscosity (110 ml/g) of starting feedstock. Mixing feedstocks containing regenerated fibres with cotton seems to decrease the spinnability of dopes. Recycled fibres can be used in the production of textiles and nonwovens for different applications, depending on the strength properties of recycled fibres.

Process

More information:

Simo Hannula

simo.hannula@vtt.fi